BATMAN V SUPERMAN

ART DIRECTOR for Batmobile. My responsibilities lay mostly with the administrative duties. Scheduling and budgeting were my greatest responsibility. I did source set decorating and a number of the practical components like the wheels and steering wheel… I also cut together a video to show the latest military technology possibly utilized on the vehicle. My ID background also allowed to suggest modes of manufacture like rapid prototyping and CNC. Both of which were possible as we developed the vehicle using Solidworks. I must give a shout out to the 3d extraordinaire Joe Hiura. Also Ed Natividad our Conceptual designer.

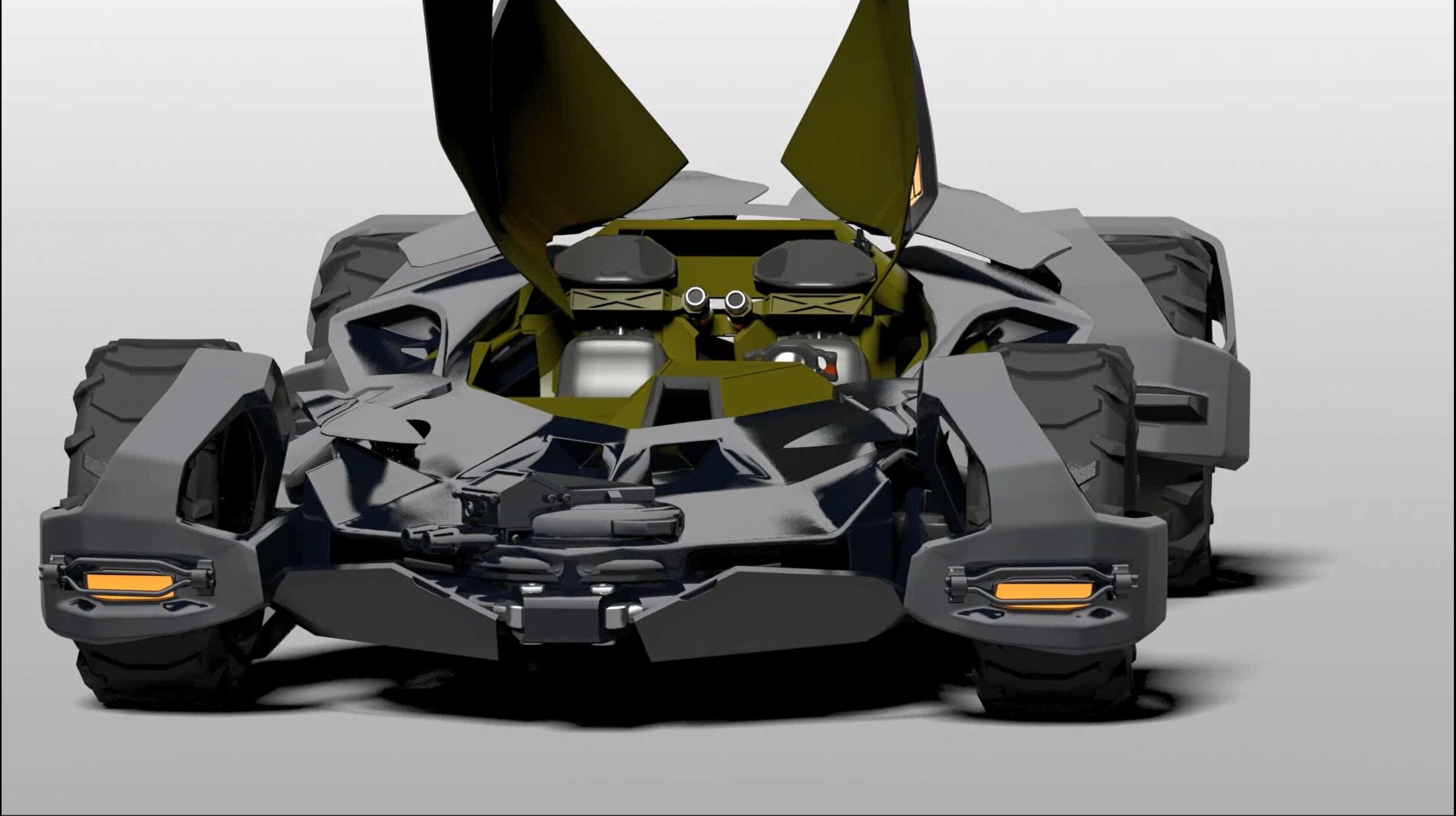

Early ideation sketch by our production designer Patrick Tatopoulos. Really captured the design direction. Patrick wanted a vehicle that could raise and lower to suit terrain. He felt the wing resembled the bat-cape and the doors open the bat ears.

Concept designed by Ed Natividad. This is where I entered. I was to art direct this piece to completion. My focus was in administrative duties. Budget and scheduling as well as managing the fabrication needs.

A video I helped compile and edit. Its purpose was to help define the capabilities of the vehicle. I consulted with Robert Johnson an expert in military technology. I wanted to show our director Zack the latest military technology the Batmobile could utilize. The needs were defined in the script. The features shown reflect those parameters.

Mockups where human involvement occur were always tested using mockups before going into manufacture. As shown by the two successive images.

This is a practice utilized by Nascar in determining the limits of the interior frame. The wooden structure is built to show the underside of the exterior skin. By having this test piece we could be assured the frame would not penetrate the car body.

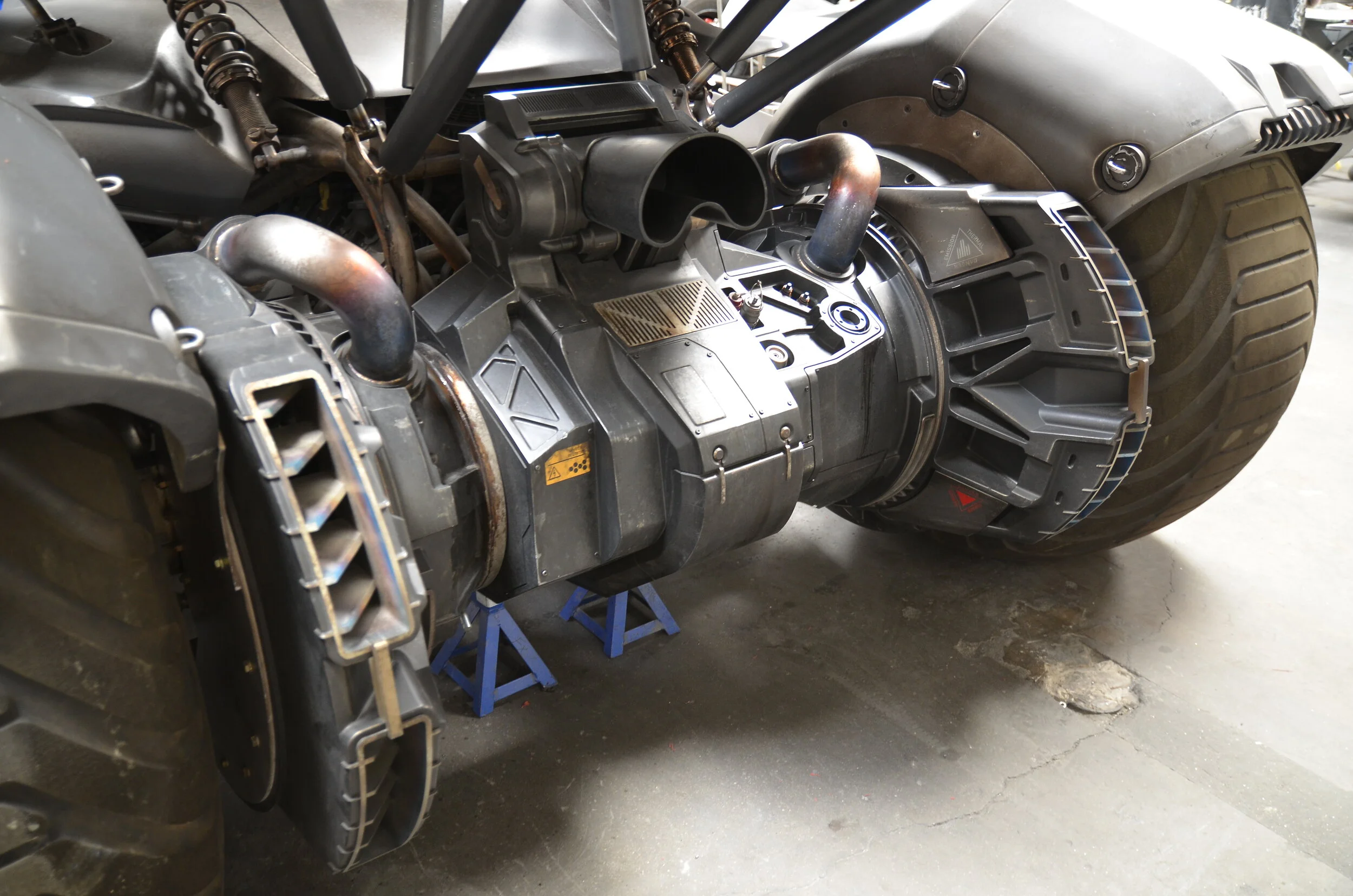

Another important feature in my opinion was all the set dressing elements attached to the vehicle. I wanted to utilize motorcycle parts. My belief is that motorcycle design performs closest to the form-follows-function principle. This is my design philosophy. To those who know these parts they are Ducati aftermarket parts.

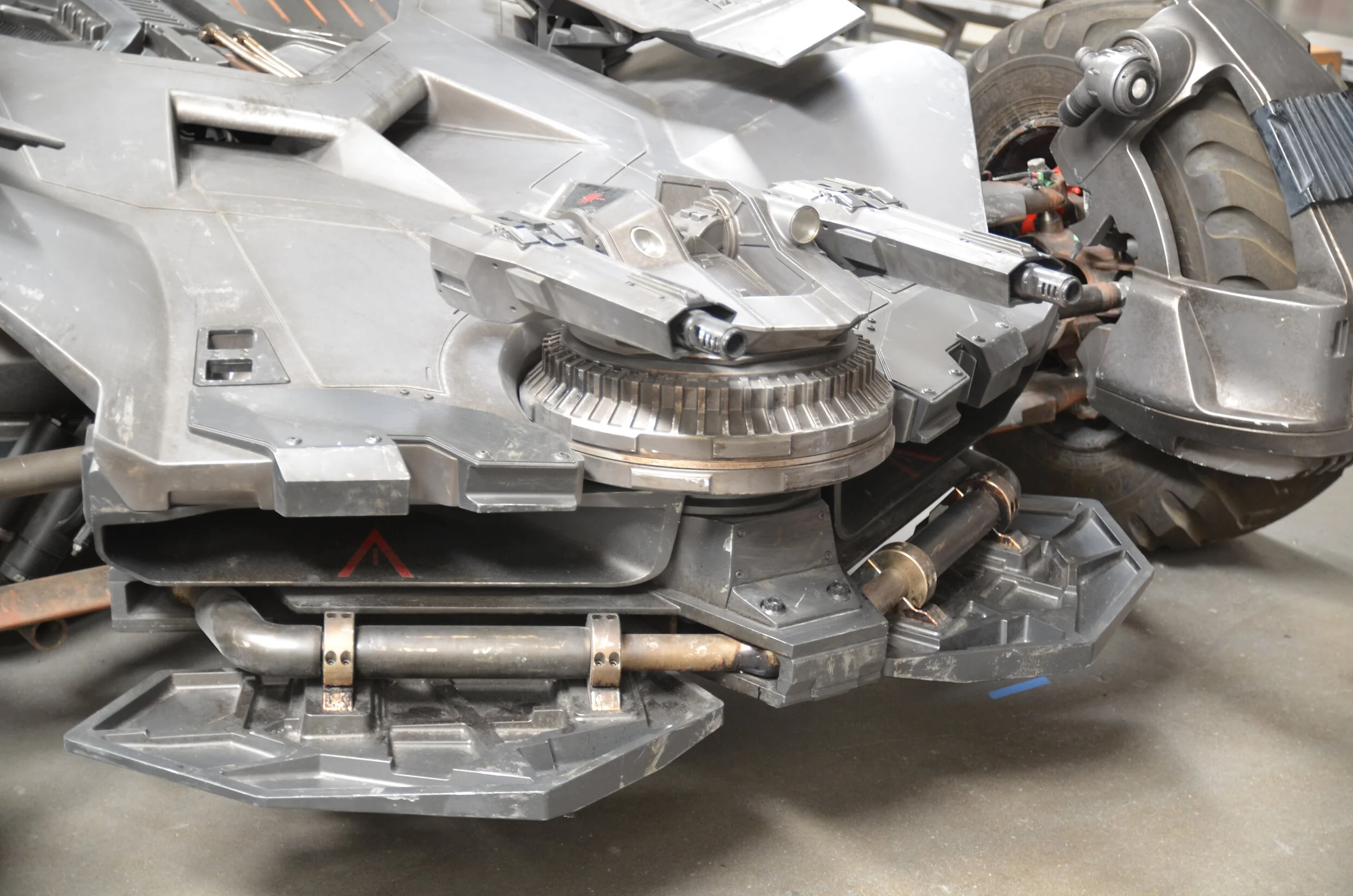

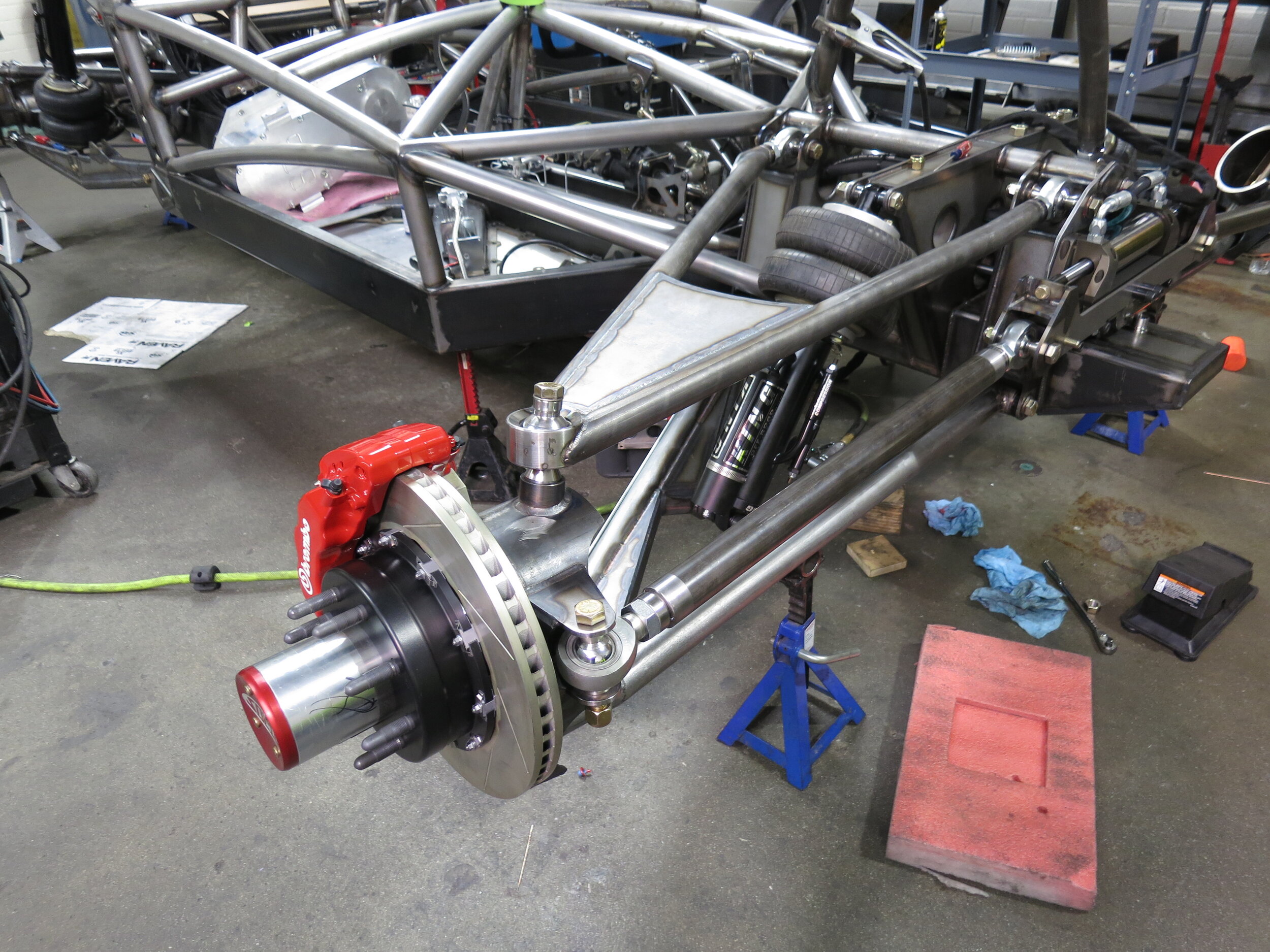

A lot of chassis testing occurred. We even set GoPro cameras on the chassis to measure suspension travel, turning radius of the wheels and tire deflection. This was to give dimensional tolerances for the skin of the vehicle. We wanted to design enough clearance to safeguard the exterior components. We did not have the time to bodywork all the car body if it did not fit or rubbed.

I am a stickler for believable destruction. I collected images that best reflected what the car body would do on impact.